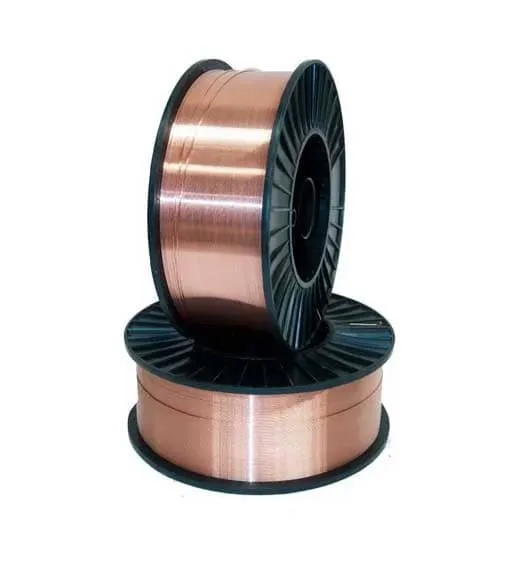

CO2 MIG Welding Wire

CO2 MIG Welding Wire

CO₂ MIG Welding Wire, commonly known as ER70S-6, is a copper-coated solid wire used in Gas Metal Arc Welding (GMAW) processes. It is specifically designed for welding mild and low alloy steels using CO₂ or mixed shielding gases (CO₂ + Argon). It is widely used in automobile, fabrication, construction, and shipbuilding industries.

Key Features:

- Excellent Arc Stability : Provides smooth welding performance with minimal spatter.

- High Deposition Rate : Enhances productivity in continuous welding operations.

- Good Mechanical Properties : Strong welds with high tensile strength and elongation.

- Low Spatter & Easy Slag Removal : Reduces cleanup time post-welding.

- Copper Coated : Improves electrical conductivity and prevents rusting.

Technical Specification

| Thickness | 0.2 - 2 mm |

|---|---|

| Wire Material | Copper/Copper Alloy |

| Flux Content (%) | 10 |

| Hardness | 20 - 40 HRC |

| Elongation (%) | 15 |

| Tolerance | 2.0 - 3.0 mm |

| Tensile Strength | 200 - 450 Mpa |